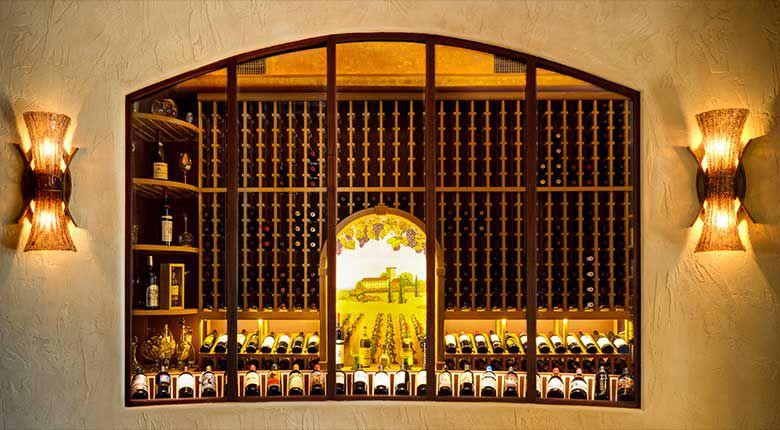

SERVICES

- PROFESSIONAL CELLAR CONSULTATION

- ARCHITECTURAL DESIGN INSTALL

- EXPERT CRAFTSMANSHIP & FABRICATION

- RESIDENTIAL & COMMERCIAL CELLARS

- COOLING SYSTEMS

- CELLAR DECOR/ART

INSULATION

Our systems consist of spray-applied, two-component products that comprise of an isocyanate (A-Side

Component) and a resin (B-Side Component). These products are not pre-formed, friction-fit batts or

board-stock insulations. Additionally, they do not involve a wet application that uses water. Instead,

during the application, a chain reaction occurs between the two components that creates a bond to the

substrate as it foams up. The product dries, cures, and hardens within 3-5 seconds. We recommend that

this product be installed only by a trained applicator.

Our polyurethane foam systems are closed-cell, with a superior effective R-value of over 6.0 per inch.

There are three major differences between WCE's foam insulation and other commonly used open-cell

insulation systems. Firstly, WCE leverages the versatility of chemistry to provide closed-cell content of

more than 90 percent for all its formulations. Conversely, open-cell foams have a typical open-cell

content of approximately 60 percent. Secondly, closed-cell content provides an R-value of over 6.0 per

inch, while open-cell offers between 3.0 and 3.9 per inch. Thirdly, and most importantly for our wine

cellar construction, closed-cell foam is virtually impermeable to air, whereas open-cell foam allows far

more air and vapor to penetrate the building interior.

A closed-cell, spray-applied polyurethane foam wall system that combines superior insulation values and

near-zero air permeability in a single application to improve building durability, energy efficiency,

occupant comfort, health, and safety.

Our polyurethane foam wall systems have undergone testing and are certified as air barriers at an

application thickness of 1 inch. Once applied, our wall systems become fully adhered and do not allow

air to flow around, behind, or through the insulation system. In contrast, most open-cell foams do not

qualify as air barrier systems since they have not undergone testing.

The U.S. Department of Energy (DOE) has revealed that traditional insulation materials' effectiveness is

reduced by 15 percent due to convection loops through and behind board and batt systems. However,

spray-applied polyurethane technology eliminates this issue by creating a fully adhered, seamless

insulation and air barrier system.

Spray-applied closed-cell polyurethane foam is the only insulation material that adds structural integrity

to the entire wall system. Tests carried out by the National Association of Home Builders (NAHB)

Research Center and the Canadian Construction Materials Centre show that when spray-applied

polyurethane foam insulation is used between wood and steel-stud wall panels and sprayed onto

gypsum wallboard and vinyl siding, it can increase rack and shear strength two to three times compared

to standard stick-built components with glass fiber insulation. Additionally, when sprayed onto oriented

strandboard (OSB), it can increase racking strength.

Mold requires three things to grow: moisture, warm temperatures, and a food source. Polyurethane

foam insulation, which has no nutritional value, is not considered a food source for mold. The use of

polyurethane as insulation eliminates condensing surfaces and reduces the potential for moisture

accumulation. It also eliminates air movement within the wall cavity. Other insulations are less

successful in controlling air infiltration and providing adequate insulation to eliminate condensing

surfaces, thus increasing the possibility of creating an environment susceptible to mold growth.

Our polyurethane technologies are formaldehyde-free formulas that emit no volatile organic compounds (VOCs) and use ZONE3® zero ozone depleting blowing agent technology.

Yes. Our wall systems do not emit Volatile Organic Compounds (VOCs). Off-gassing from this product has been measured at 0.000 parts per million. The product is inert.

Polyurethane insulation meets Class 1 flame and smoke characteristics. However, once installed, it must

be covered by a 15-minute thermal barrier or ignition barrier, depending on the application. Please

check with your local Building Codes for the final determination.

Spray-applied polyurethane foam systems require specific application equipment, including pumps, proportioners and spray guns.

WCE's professionally trained installers always use personal protective equipment (PPE) to avoid any

contact with the skin and eyes and prevent inhaling the isocyanate vapors.

During spraying, WCE always works with adequate ventilation and uses protective gloves, face masks,

and additional required PPE items.

REFRIGERATION

SELECTING & INVESTING IN THE RIGHT COOLING UNIT.

Through-the-wall cooling systems are the most cost-effective and easiest to install. They are shipped fully-charged and ready to use in a self-enclosed case.

The downside of through-the-wall cooling units is that they take up space inside the cellar, and noise from the cooling unit can be heard inside and outside the wine cellar. They also require a hole in the wall to fit the cooling unit and sufficient space on both sides of the wall for proper ventilation.

Split cooling systems are built so that some of the components are located outside the wine cellar and some inside the cellar. The 2 sets of components are connected by 2 refrigerant lines that Wine Cellar Expert staff & qualified professionals will charge and braise on-site. Our certified installers may also need to set up power and drain lines.

The main advantage of split systems is that you can place the condensing unit in a remote location, which mitigates noise from the compressor.

Ducted cooling systems are generally the most aesthetically desirable wine cooling systems as they can seamlessly fit into almost any preferred architectural or design environment. The entire cooling unit is located remotely, and cold air is ducted into the wine cellar, ensuring that the cellar is not subject to noise from the cooling unit. Moreover, these systems maximize the space inside the wine cellar for wine storage since the cooling unit doesn't take up any space inside the cellar.